PLYWOOD MATERIAL IN FURNITURE

Plywood wood is widely applied from construction projects to furniture production. Used for products requiring high load-bearing capacity such as floors, partitions, table surfaces... Additionally, boards are also used as molds for pouring construction materials. Besides that, with the sturdiness of plywood, it is also used to build boats and vessels.

The structure of Plywood is usually divided into three components:

- Core (or center): consists of many thin wood veneer layers with thickness of about 1mm.

- Surface: is the natural wood layer.

- Adhesive: the types of glue commonly used for plywood are Urea Formaldehyde (UF) glue and Phenol Formaldehyde (PF) glue.

Raw materials for plywood production are usually various types of wood, including common woods such as pine, poplar, basswood, eucalyptus, acacia, etc. Based on different core wood components, Plywood boards are also divided into many different corresponding types.

Plywood production includes 4 main stages:

- Hot pressing process: After each core board layer is run around the glue roll on the board surface. Core board layers are laid evenly layer by layer, without overlapping. Put on the press plate under temperature: 100°C. Time from 15-20 minutes depending on the glue component to time the glue bonding (called glue curing time).

- Core board surface treatment process: After hot pressing is completed, we proceed to sand the board surface. Sandpaper here we can use roll sandpaper, drum sandpaper: 240, or 280. Sand 02-03 times to create a flat surface of the board.

- Surface veneer lamination process: When sanding treatment is completed, proceed to apply 01 even glue layer on the pressed core board surface. Then cover the veneer layer and proceed with hot pressing and time the glue curing.

- Pressed board finishing process: After sanding treatment, we proceed with final finishing sanding 02-03 times depending on the purpose of use, and edge cutting finishing.

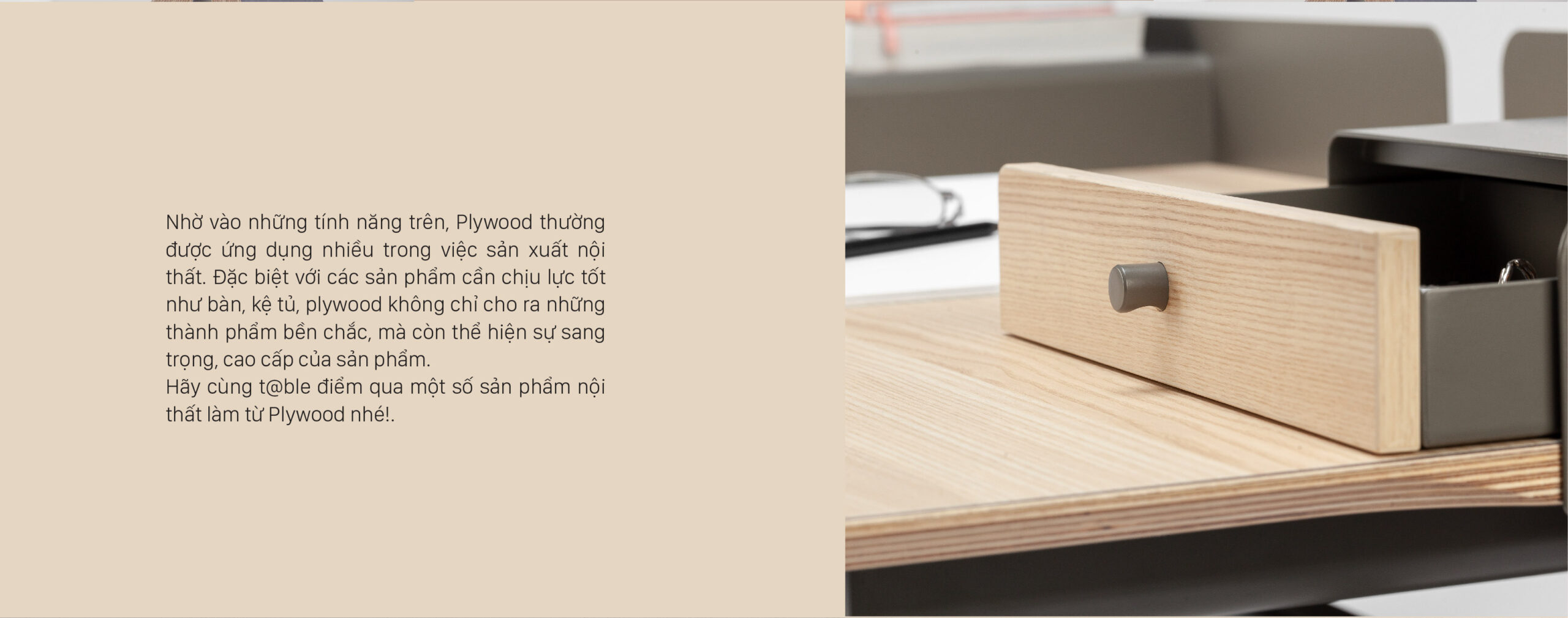

Thanks to the solid core component structure and hydraulic pressing technology, Plywood has good load-bearing capacity and high durability. Additionally, the waterproof adhesive helps Plywood be durable in humid environments. Furthermore, plywood also has good screw-holding and adhesion capabilities. At the same time, the cost of plywood is much more reasonable compared to rare natural woods. As well as the elegant beauty that easily fits with modern interior spaces, it is very popular today, especially for young families.

TIN TỨC LIÊN QUAN

CLEAR COLLECTION – SOLUTIONS FOR COMPREHENSIVE OFFICE SPACES

Clear office furniture collection with diverse table styles from single table, 4-person desk cluster, 6-person desk cluster to management desk, office meeting table. This is a complete solution for comprehensive office furniture. With a minimalist yet modern design, Clear is suitable for many different spaces and styles.

Office Furniture Trends 2025

Open workspace creates a comfortable feeling for employees, without constraints. People can easily interact with each other when working, employees can easily gather at any employee's desk to discuss and have group meetings.

CONFERENCE TABLE DESIGN OPTIONS

Meeting tables are products that are always carefully selected in office furniture, because meeting rooms are places to receive customers and partners, where important meetings take place.

CLEAR PRODUCT SYSTEM – CLASSIC, SIMPLE YET VERSATILE DESIGN

Clear Collection includes a full range of desk types single desk, workstations, to meeting tables, management desks, and high tables. It provides diverse and comprehensive choices for a complete office space.